-

Manufacturing for small series

Manufacturing for small series

and prototypes -

Manufacturing for small series

Manufacturing for small series

and prototypes

Manufacturing

In our workshop equipped with modern machines we specialise in the manufacture of small series and prototypes. Construction of moulds, parts production and assembly is done here in Belgium to provide optimal flexibility to our clients. By using technology like high speed milling, integrated CAM and servo-hydraulic injection moulding machines we go rapidly from design in 3D to final parts, in-house. Next to plastic and metal parts we provide all additional steps needed to provide a turn-key solution for you.

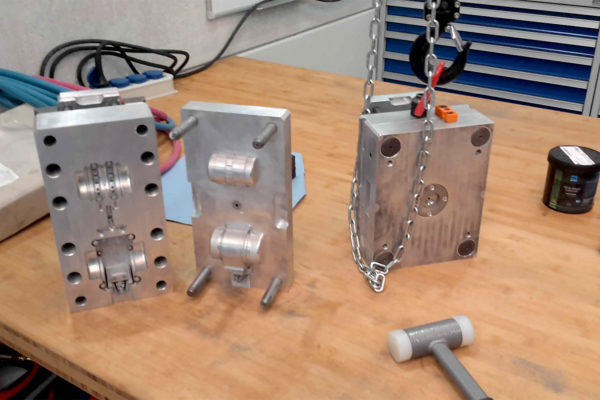

Mould making

We specialise in the manufacturing of aluminium injection moulds for our small series production and prototypes. By using high speed milling machines, we manufacture moulds faster and with more details then conventional machines.

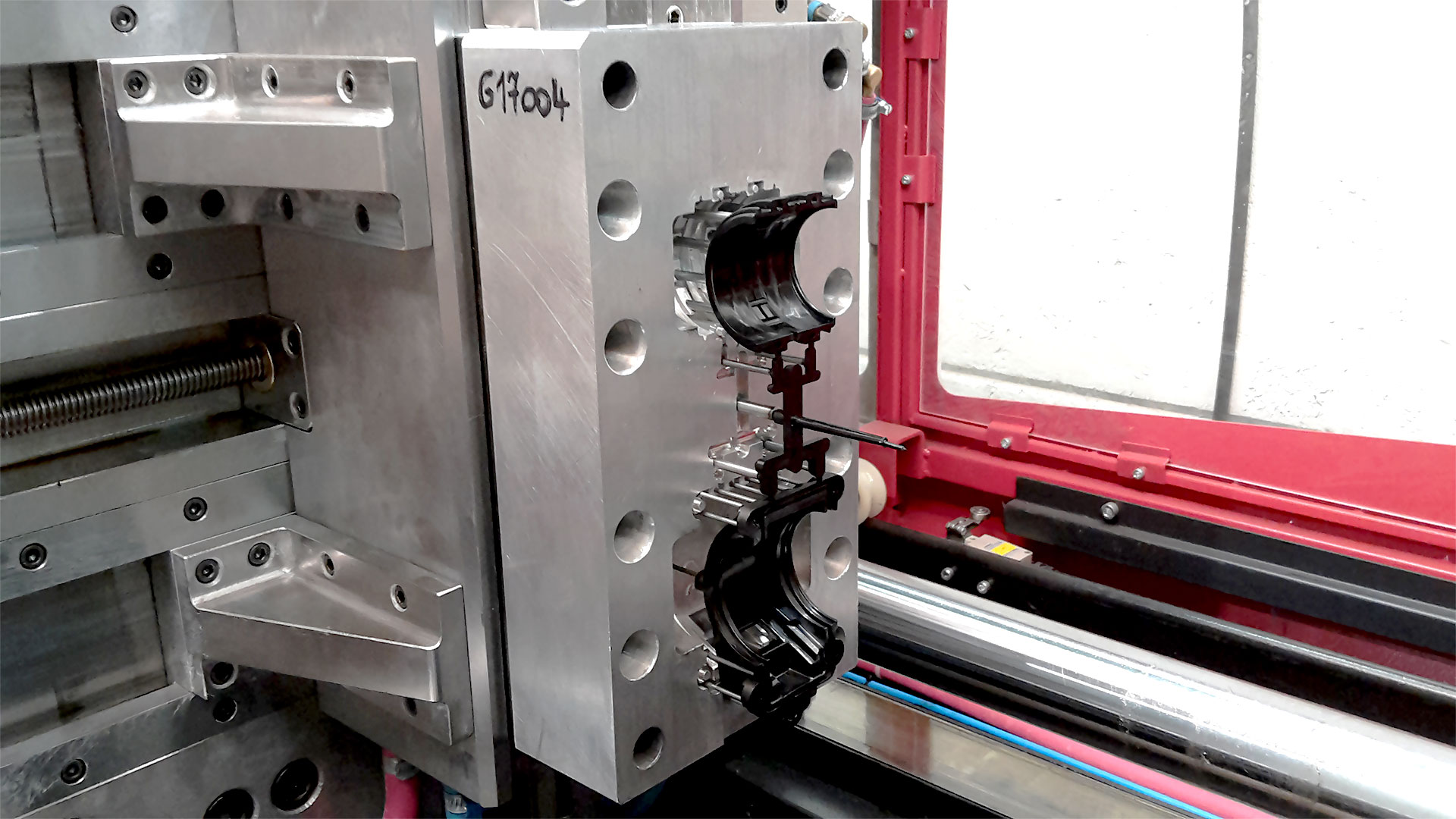

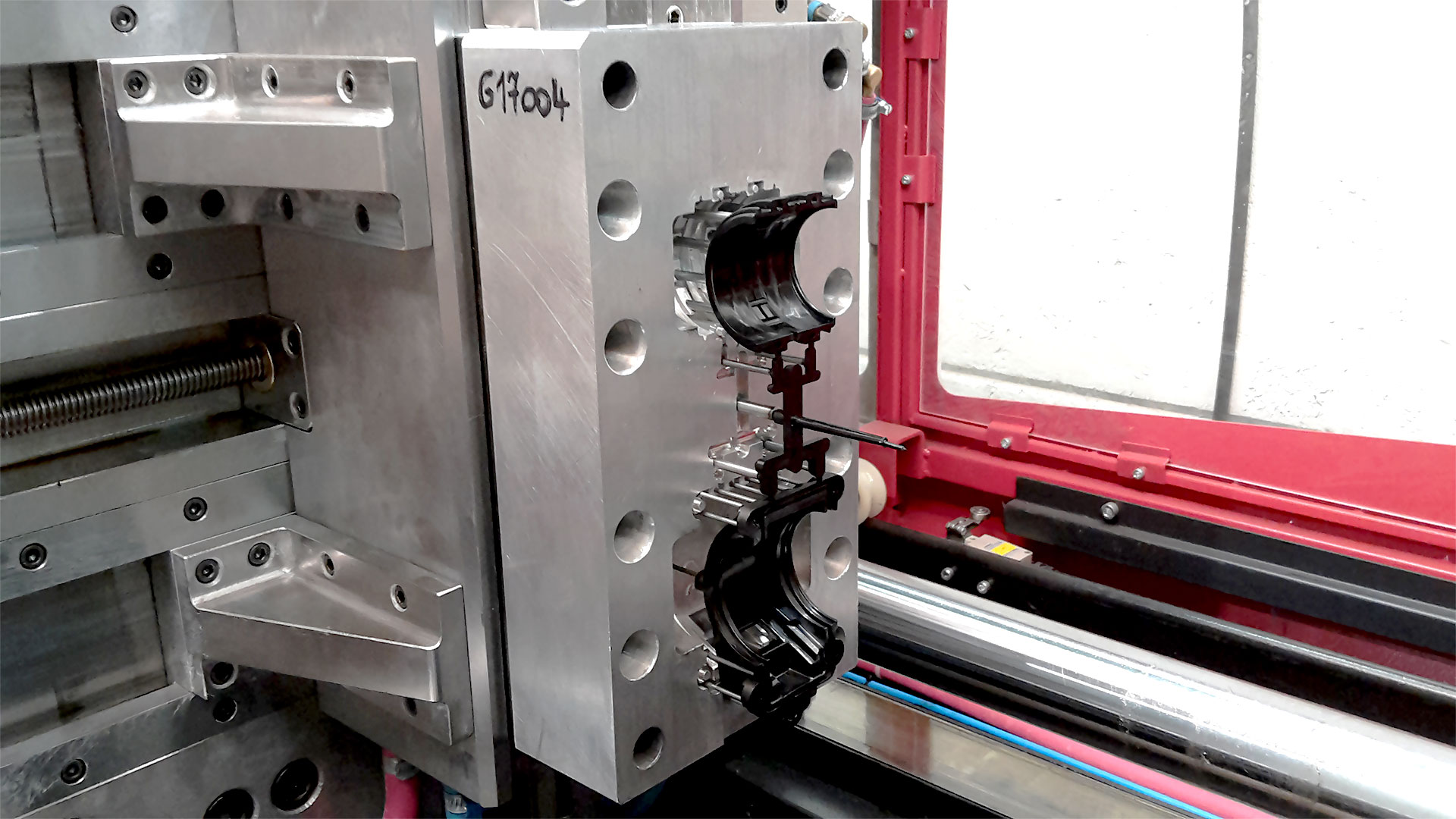

Injection moulding

Injection moulding of parts is done on a modern servo-hydraulic injection moulding machine. Sizes: up to 500x350mm (part), 225cm³, 140T closing force, materials like PE, PP, ABS, PC-ABS, PC, PA6, POM, SAN and other materials in multiple colours.

Assembly

To complete your product we also offer assembly service and finishing operations. This gives us the ability to offer a turn-key solution from idea to market.