-

Validation to improve results

Validation to improve results -

Validation to improve results

Validation to improve results

Validation

To improve engineering and manufacturing we believe that validation is important and leads to improved performance, results and lifecycle of a product. In our validation process we use our knowledge and experience in computer simulation, testing, DFMEA, qualification and other techniques. By using both preventive and corrective actions during the development, the optimal product can be achieved.

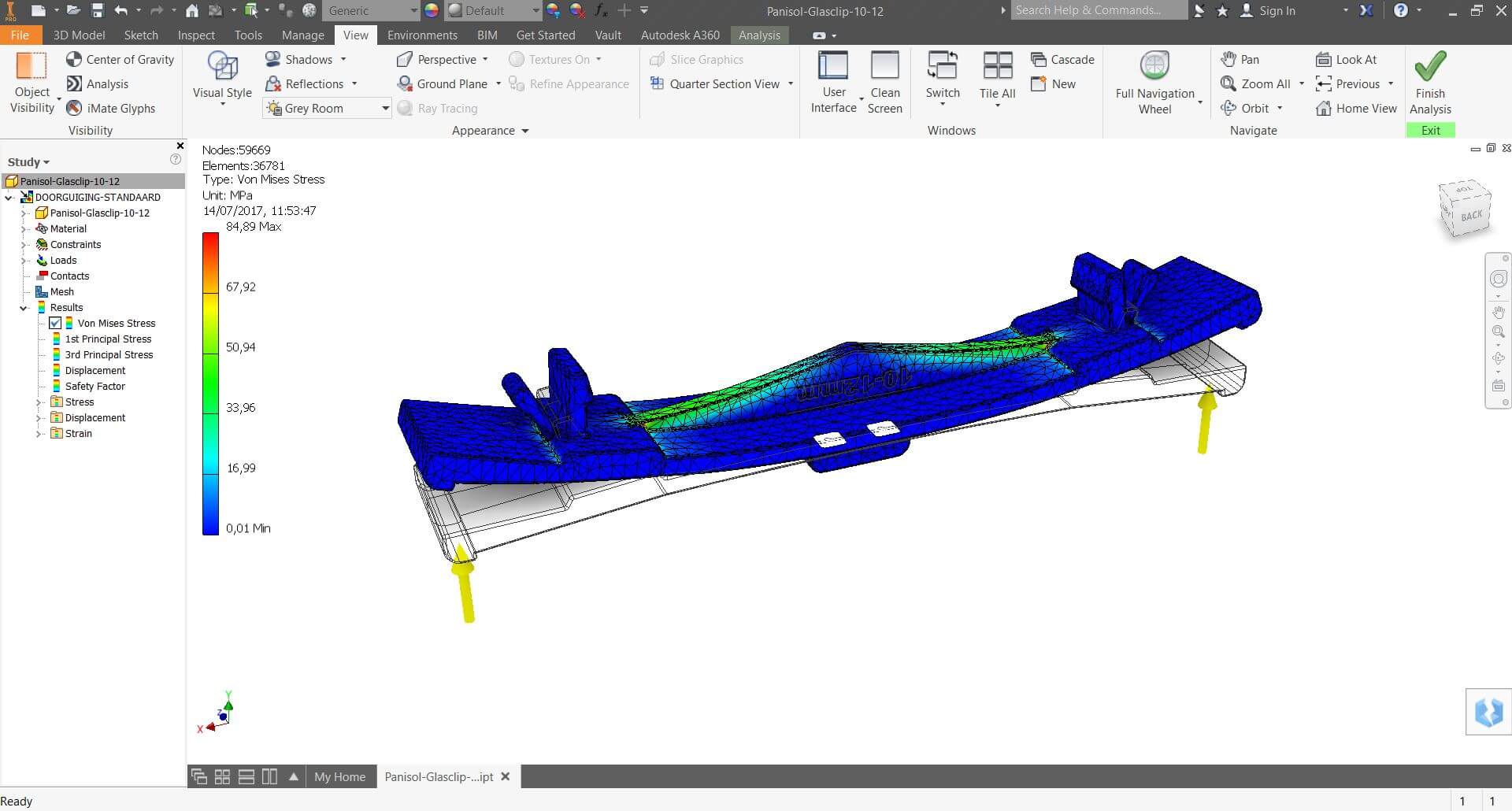

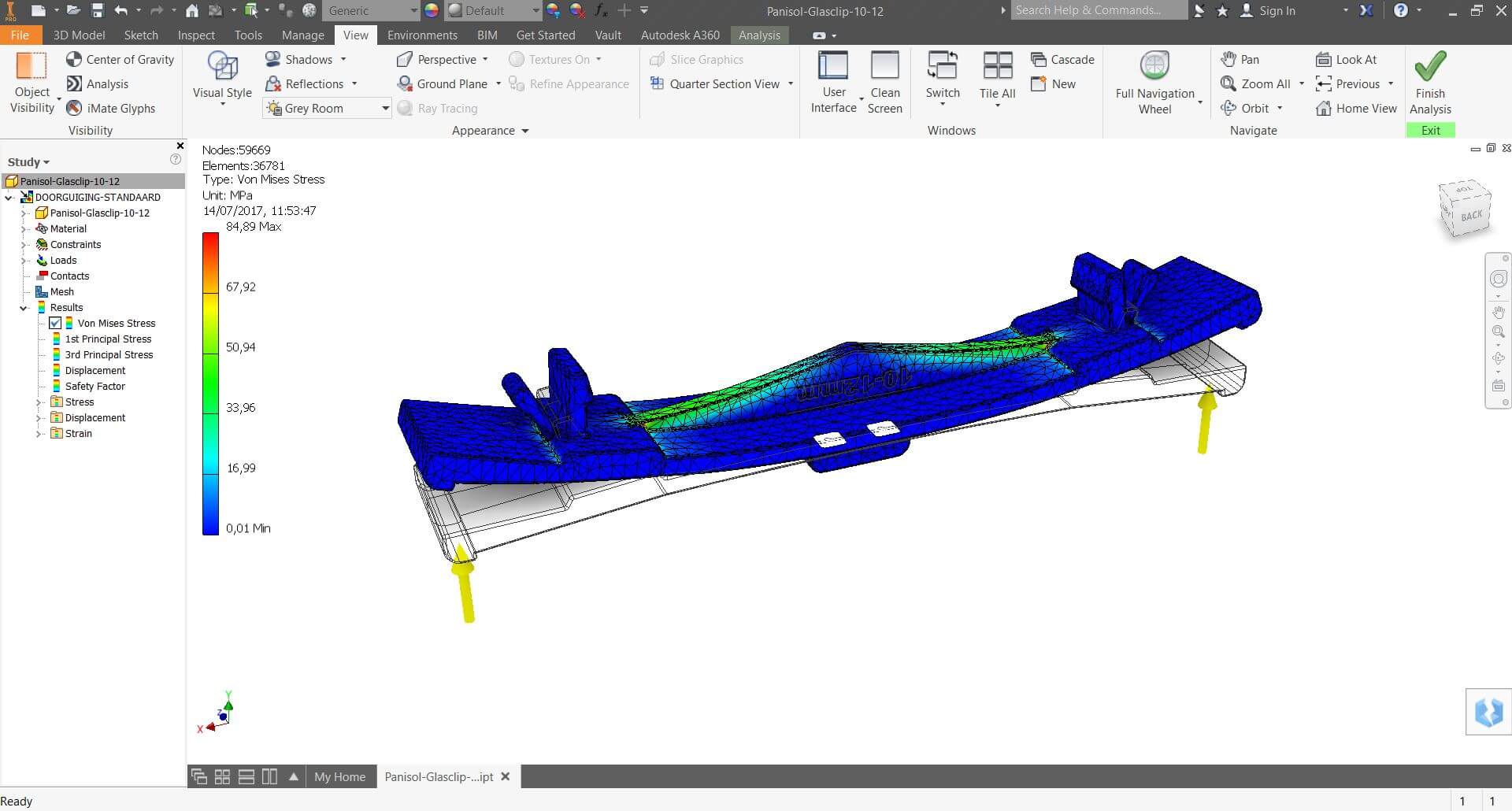

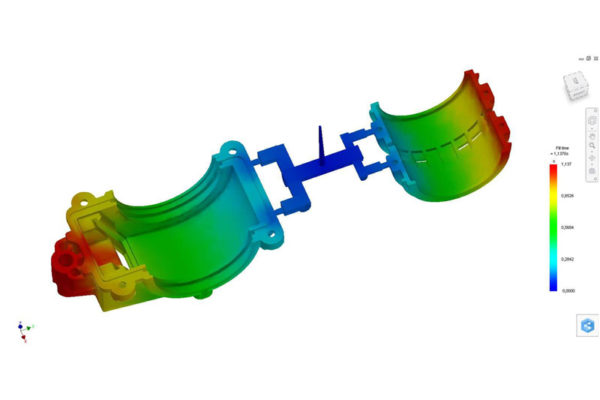

Simulation

We offer computer simulations in the domain of static/dynamic, thermal and mold-flow. By combining this with our specific material knowledge in plastics we can simulate results before a product is physically made.

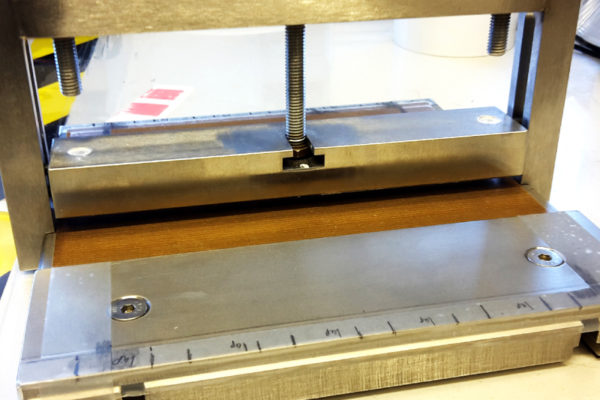

Testing

For products that needs to be tested during development, we offer testing services for your product such as standard mechanical tests up to tailor made testing equipment.

Qualification

Some products need qualification to specific requirements or regulations. We support you in this process thru in-house and external programs to make sure your product is ready for the market.